As the A321XLR programme continues to gather pace, Airbus is advancing its industrial system and expanding ramp-up capacity with a new automated A321XLR equipping hangar.

The new hanger was opened on the 30th of August by Hamburg’s First Mayor Peter Tschentscher and German Aerospace Coordinator Anna Christmann.

Peter Tschentscher, First Mayor of the Free and Hanseatic City of Hamburg, André Walter, Head of Airbus Commercial Aircraft Production in Germany, Anna Christmann, Federal Government Coordinator of German Aerospace Policy and Gary O’Donnell, Head of A321XLR Development formally opening the new hanger – Image, Airbus

The move will support the airframers programme to ramp up its capacity for the rate ramp-up in the A320 programme to 75 in 2026, with the facility able to handle eight fuselage sections to be handled simultaneously.

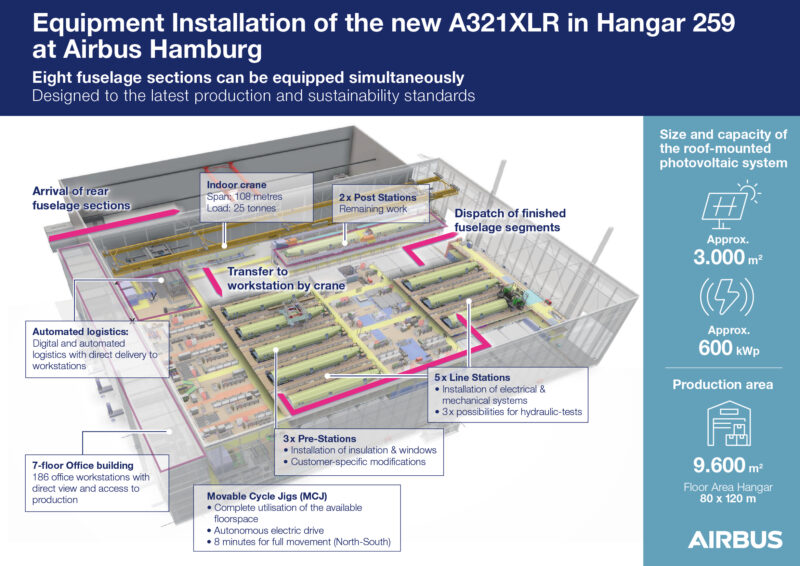

The hanger – with 9,600 m2 of production space is where all the components of the rear fuselages of the A321XLR aircraft (which will be built in Hamburg) will be installed and mounted. The hangar is equipped with a full range of state-of-the-art technologies for operations and manufacturing, such as automated logistics, fully digital systems, and test stations that can output the status of each fuselage section (both in terms of logistics and resources) at any time.

There’s a great fly-through Airbus has published.

Moin moin! Exciting news for our Hamburg team 🇩🇪 as the site opens a new facility ready to equip up to 8 #A321XLR fuselages simultaneously, joining our global ramp-up effort! ✈️

Built and designed with the latest sustainability standards at the heart, this new automated… pic.twitter.com/CC3OxnoHiJ

— Airbus (@Airbus) August 31, 2023

The almost 24-metre-long fuselage sections are equipped with all electrical and mechanical systems, as well as other elements such as windows, floor panels or external antennas, on an automated ‘pulse line’ consisting of eight stations. Each fuselage section is extensively tested directly after the installation of the systems. The fuselage sections are then transferred to the final assembly line in Hamburg.

In Quotes

“Airbus’ Hamburg site plays a significant role in the development and production of the A321XLR. With our new, state-of-the-art equipment installation hangar, we are now expanding our capacity to manufacture A321 fuselages and making an important contribution to supporting our ramp up. At the same time we are reaffirming the importance of Hamburg for Airbus,” said André Walter, Head of Airbus Commercial Aircraft Production in Germany. “The design of the building reflects the latest standards in production and sustainability.”

Dr Peter Tschentscher, First Mayor of the Free and Hanseatic City of Hamburg: “Hamburg is the central location for Airbus’ single-aisle development and production. With the A321XLR, the new flagship of the A320 Family will be assembled at the Finkenwerder site, setting new standards in terms of sustainability, efficiency and range. The start of production in the new equipment installation hangar is an important project for Hamburg as the world’s third largest civil aviation center.”

“This investment in the A321XLR equipment installation hangar at the Airbus Hamburg site is an important milestone towards transitioning aviation to climate neutrality. This transformation is the key to making Germany a future-oriented and competitive aerospace location,” said Anna Christmann, the Federal Government Coordinator of German Aerospace Policy. “I am delighted that Airbus is positioning itself as a trailblazer in sustainable aviation and that we are pulling together to accelerate progress toward climate-neutral aviation even further.”

Towards Rate 75 and the A321XLR

With Airbus targeting a production rate of 75 aircraft a month globally in 2026, equipping aircraft in a timely manner is going to be key as part of the delivery of the new aircraft.

And there is going to be a lot of them going through this new facility, being able to handle eight fuselages at once.

As to the A321XLR – it’s an important step, as airlines wait patiently for the type that will fill in the thin-and-long routes it is expected to fly, with up to 4,700 nm range – and with plenty of customers waiting for the type (from the launch customers of IAG, American Airlines, United Airlines, Ingido Partners), to the newest orders from Icelandair.

There’s a lot of demand to be met from the A320 family, as Airbus goes through its backlog. Hopefully, this new facility will aid in the production of these eagerly awaited aircraft.

Welcome to Economy Class and Beyond. Your no-nonsense guide to network news, honest reviews, in-depth coverage, unique research, as well as the humour and madness I only know how to deliver.

Our Social Media pool has expanded. You can find us across most networks as @economybeyond on Twitter, Mastodon, BlueSky, Threads, as well as Instagram!

Also, remember that we are part of the BoardingArea community, bringing you the latest frequent flyer news from around the world.