Airlines are constantly looking for ways to reduce their environmental footprint and weight and turn to others to help. Soisa Aircraft Interiors launched a new armrest… which is primarily made of corn particles.

Yes. Corn.

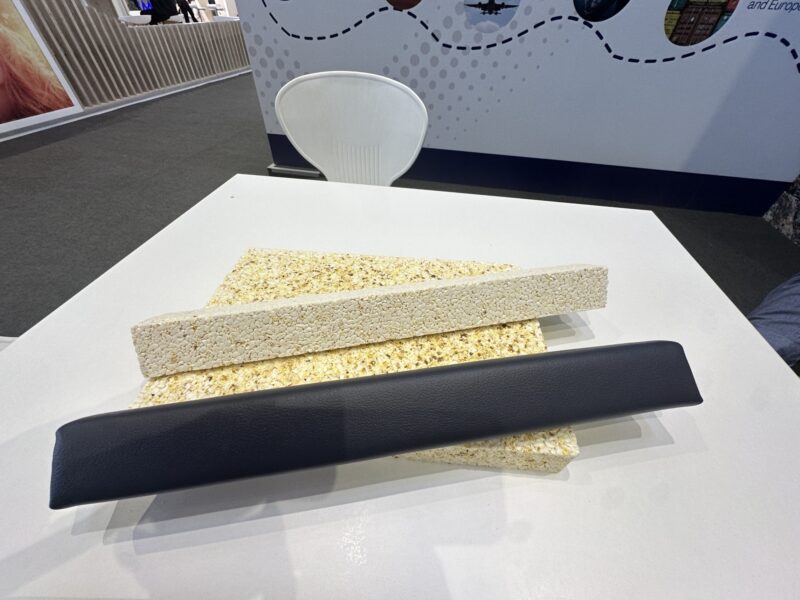

One of these is not made of corn…. have a guess.

Soisa Aircraft Interiors launched its new ‘organic armrest’. The armrest is made of a base of corn particles, materials that were otherwise destined for the landfill. Instead, the materials are upcycled.

In 2023, Soisa produced approximately 5,200 armrests for various airlines, utilising around 2,000 square feet of polyethylene foam, which resulted in nearly 2,600 kg of CO2 emissions annually. By transitioning to a biodegradable material derived from corn waste, an eco-friendly, non-food resource, Soisa will significantly reduce its carbon footprint.

The corn-based material may also offer significant potential cost benefits, enabling Soisa to produce specialised moulds for each part number and thermoform the corn, streamlining their manufacturing processes.

So, how does it work in practice?

Soisa showed off their demonstration unit at Aircraft Interiors Expo. First, they obtain the corn particles and compress them down. You end up with a product like this.

As corn can be moulded, you can mould it into any shape – such as an armrest.

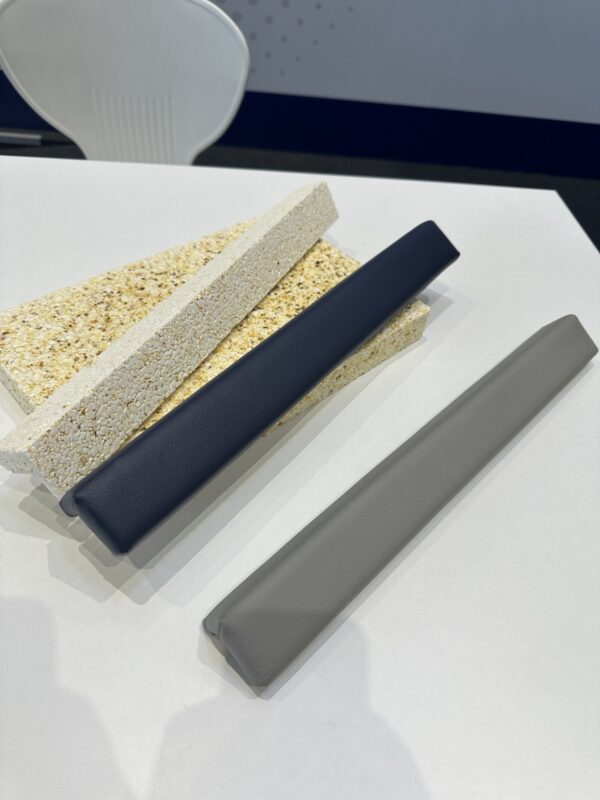

From here, foam can be added for comfort. Add a leather cover… and you get one of these.

That’s the main part of an arm-rest module, which can be integrated into a seat as needed.

This compares with a traditional unit (in grey), which is traditionally formed.

In Quotes

Jacobo Mesta, Sales and Growth Strategy at Soisa, said:

“As the aerospace industry intensifies its focus on sustainability practices, airlines worldwide are increasingly striving to minimise their environmental footprint. Soisa is at the forefront of this movement, pioneering engineering in aerospace by thinking outside the box and exploring alternatives which promote a sustainable future.

“This innovative design not only highlights our commitment to environmental responsibility but also ensures that our products retain their aesthetic appeal, comfort, and high quality.”

Sustainability in action

We talk a lot about sustainability in the air – and these efforts have been focused on reducing weight so far, with additive manufacturing making major inroads as we see much more 3D printing take to the sky as qualified parts.

Others are exploring the use of recycled parts (which we’ll explore in later writeups), but the concept of upcycling is only starting to be considered at length in the aviation industry – with corn particles, in this case, being the base material that helps them form seat armrests.

This opens up further ideas on where this material can be used in aviation, either as a weight saving or as a sustainability goal – pricing it can meet safety standards.

It’s an interesting use of technology, which takes us beyond traditional thermoplastics and explores how we can utilise waste into

Disclosures: Economy Class and Beyond was a guest of Soisa Aircraft Interiors at AIX 2024.

Images, Economy Class and Beyond.

Welcome to Economy Class and Beyond. Your no-nonsense guide to network news, honest reviews, in-depth coverage, unique research, as well as the humour and madness I only know how to deliver.

Our Social Media pool has expanded. You can find us across most networks as @economybeyond on Twitter, Mastodon, BlueSky, Threads and Instagram!

Also, remember that we are part of the BoardingArea community, bringing you the latest frequent flyer news from around the world.