A look at the new Recaro Aircraft Seating Crash-test facility – Economy Class and Beyond at Recaro Aircraft Seating

To Stuttgart and Schwabisch Hall

In this trip report:

- An Invite to Germany

- Testing and Paperwork

- Off to Heathrow, Terminal 5, and the South Galleries Lounge

- BA920 London Heathrow to Stuttgart (Club Europe)

- The joy of German Immigration, Into Stuttgart and the Novum Hotel Rieker, Stuttgart Hauptbahnhof

- Off to Schwabisch Hall, qubixx stattemitte Hotel

- Economy Class and Beyond at Recaro Aircraft Seating

- The inauguration of their new customer facility

- The Recaro Hybrid Seat Show

- Exploring the Crash-Test facility

- Back to Stuttgart and the joy of pigeons

- Off to Stuttgart Airport

- BA921 Stuttgart to London Heathrow (Club Europe)

- Welcome to Brexitainia, The Premier Inn Heathrow

- Off Home again

- Innovation is the driver

The Recaro 707 tail (ex Hamburg Airport).

One of the newest features of Recaro’s new facility at Schwabisch Hall is their new seat crash and testing facility. This is in addition to a flame lab that has been opened.

Mr Porche. With Recaro seating inside.

Whilst computer modelling crashes is helpful, nothing helps like a real-world test to gather data and analyse how a seat will behave in the real world, as well as those seats gaining certification

Enter the crash facility.

The crash test facility. If you want to see a picture of The Wandering Aramean on the rig… head here.

Like a lot of vendors, Recaro used to use a 3rd party to validate their test requirements. By bringing it in house, Recaro can reduce the costs of using an external party, as well as to conduct the number of tests they require – both for education and for regulatory reasons,

The company expects to operate 200 tests a year at the facility.

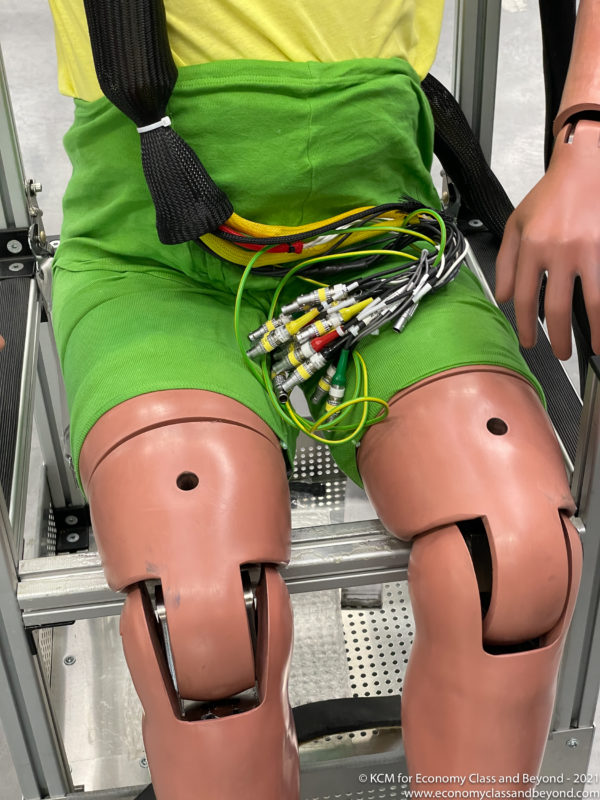

With the rig capable of testing 16G crashes, there are a lot of sensors to set up, as we can see from the crash-test dummy.

As well as rigging the sensors of the dummy, there is lighting and a camera to capture the information – generating gigabytes of information at a time, with 1000 frames per second to allow for post-test analysis.

And a lot of light to capture the images.

The system is powered by a nitrogen ram (this being a lot more stable than oxygen or other gas, with the majority of nitrogen recovered and reused post-test.

A test lasts three seconds and is very controlled so there are no loose items or bodies around – as this data can be used to qualify or develop a seat that will go to market.

Facilities like this cost a lot of money – and for Recaro – it’s a major investment. By taking the testing in house, they will recover the cost of developing the seat – and in turn that could come at a reduced cost to the customer or OEM who wants a Recro seat installed in their aircraft.

FULL DISCLOSURE: Recaro Aircraft Seating kindly invited Economy Class and Beyond, as a guest to their facilities, offering a stipend to assist with expenses.

All opinions and thoughts are the author’s own and are not directed by Recaro Aircraft Systems.

Welcome to Economy Class and Beyond – Your no-nonsense guide to network news, honest reviews, featuring in-depth coverage, unique research, as well as the humour and madness as I only know how to deliver.

Follow me on Twitter at @EconomyBeyond for the latest updates! You can follow me on Instagram too!

Also remember that we are part of the BoardingArea community, bringing you the latest frequent flyer news from around the world.