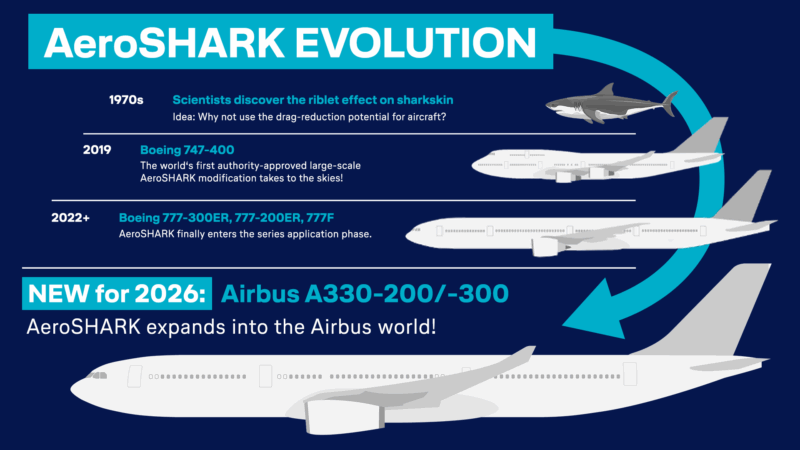

In trade shows, we’ve seen Lufthansa Technik show off its AeroSHARK technology developed in collaboration with BASF Coatings. To expand the use case of AeroSHARK, it is going through the certification process for use on the Airbus A330ceo family.

|

|

AeroSHARK film being installed – Image, BASF Coatings/Lufthansa Technik.

AeroSHARK is a film that is applied to an aircraft fuselage. It imitates the special characteristics of sharkskin, significantly reducing aerodynamic drag through its riblet structure. The principle of drag reduction through riblets has been scientifically recognised for decades.

Lufthansa Technik and BASF Coatings have successfully applied this principle for the harsh conditions of daily airline operations. It is deployed on the aircraft fuselage and engine nacelles. With it installed, AeroSHARK achieves a reduction of about one percent in fuel consumption and CO₂ emissions, which could further increase with the certification of additional surface areas.

So far, the film has been installed as a retrofit option on Boeing 777-300ER, Boeing 777-200ER and Boeing 777F. With the Airbus A330 being the second-most delivered wide-body aircraft type after the Boeing 777, there is a market for the film to be made available on the type, given there are plenty of Airbus A330-200 and Airbus A330-300 in active service.

AeroSHARK deployment – Graphic, Lufthansa Technik

Authority certification will be sought through a Supplemental Type Certificate (STC), enabling series modification to the A330-200s’ and A330-300s’ fuselage and nacelles. Modifications for each aircraft model and additional application area must undergo their own supplemental type certification.

For the A330, this process is expected to be completed in 2026.

In Quotes

Andrew Muirhead, Vice President Original Equipment Innovation at Lufthansa Technik, said

“The choice of the A330ceo as the next candidate for AeroSHARK certification is strategic, given the type’s widespread use and significant leverage on global fuel consumption and emissions. With about 1,000 A330-200 and -300 aircraft in service worldwide, the potential for operational cost savings and substantial environmental benefits is vast”

Frank Naber, Senior Vice President Global Surface Treatment at BASF Coatings, added.

“The sharkskin technology represents a significant step forward in the efforts to improve fuel efficiency and reduce emissions in commercial aviation. With the certification for the A330ceo, it will soon be possible to extend these benefits to a wider number of aircraft and to further contribute to more sustainable aviation practices”

Obtaining the official approval from aviation authorities is required to introduce any aircraft modification for use in commercial aviation. The certification process involves detailed analyses and test campaigns to ensure compliance with stringent aviation safety standards.

Expanding AeroSHARK’s proven benefits to more aircraft

To date, large-scale AeroSHARK modifications have been successfully applied to 28 Boeing 777 aircraft of several airlines and one Lufthansa Boeing 747, which served as a testbed. The number is steadily growing, demonstrating the riblet film’s efficiency in daily operations.

As of August 2025, AeroSHARK-modified aircraft have accumulated over 232,000 flight hours, saving more than 13,000 metric tons of jet fuel and reducing CO₂ emissions by over 42,000 metric tons.

But how does it feel?

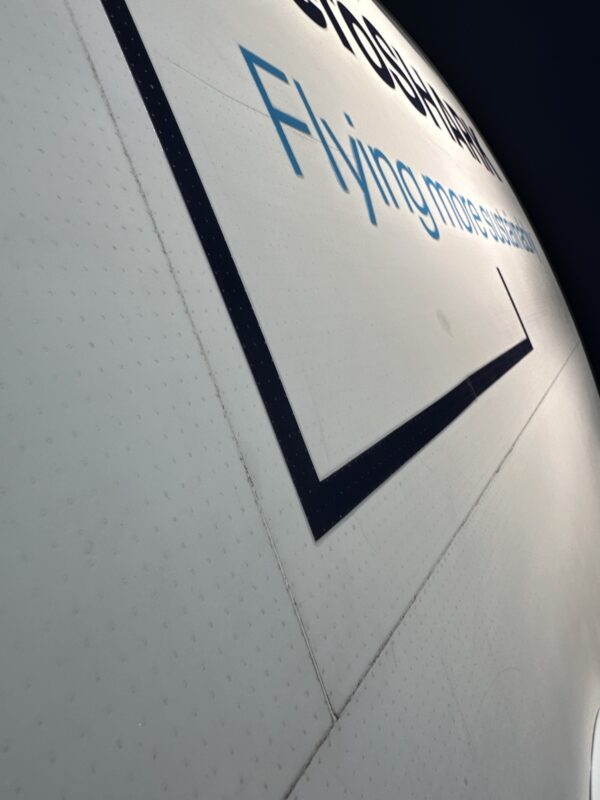

If you can touch it, you know it’s there. Here it is installed on some test fuselage at Aircraft Interiors Expo.

AeroSHARK installed on a demonstrator fuselage – Image, Economy Class and Beyond.

Aeroshark close uos – Images, Economy Class and Beyond.

There is certainly a difference, as you can see the film coating, and when touching it, there are those riblets… whilst not visible to the eye, they are to the touch.

Whilst there may be a small weight penalty for having the film installed, airlines such as Lufthansa, SWISS, Austrian, EVA Air, LATAM, and ANA are finding that those 1% savings (however small they may be) add up over time. Over the lifetime of an aircraft (even if installed during a mid-point), those numbers can add up fast, reducing the fuel bill, especially on the longer distances that the Boeing 777 and Airbus A330 can fly.

With the fuel bill being one of the biggest outgoings for an airline, I suspect there will be more than a few airlines that will have this on their analysis list, especially those that are keeping the A330ceo in service for some time to come.

Leader Images, Lufthansa Technik

Tradeshow Images, Economy Class and Beyond. We thank Lutfthasna Technik for access to their stand during Aircraft Interiors Expo.